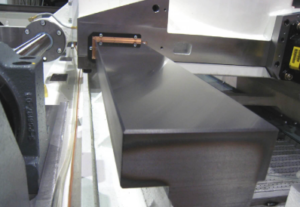

Box Ways

Pros

- Higher rigidity and damping: Box ways offer superior stiffness and absorb vibrations better than linear ways, especially under heavy loads and during heavy cutting. This is crucial for maintaining accuracy and surface finish, particularly when working with hard materials like steel.

- Longer lifespan: Box ways are traditionally more durable and can last longer than linear ways, especially with proper maintenance. They can be reconditioned and rebuilt, extending their life even further.

- Lower cost: Box ways are generally less expensive than linear ways, making them a good option for budget-conscious projects.

Cons

- Slower speed: Box ways have higher friction than linear ways, resulting in slower rapid traverse speeds and potentially longer cycle times.

- Stick-slip: Box ways can exhibit stick-slip behavior, where movement isn’t smooth and consistent, which can affect accuracy and finish quality. This is especially true during low-speed movements. This is mostly a result of poor maintenance practices.

- More maintenance: Box ways require regular lubrication and adjustment to maintain performance, adding to maintenance costs.

Linear Ways

Pros

- Faster speed: Linear ways have lower friction than box ways, enabling faster rapid traverse speeds and potentially shorter cycle times. This is beneficial for applications where speed and efficiency are crucial.

- Less maintenance: Linear ways require less maintenance than box ways, as they are often sealed and require less lubrication.

- Quieter operation: Linear ways generally operate quieter than box ways, improving the working environment.

Cons

- Lower rigidity and damping: Linear ways are less stiff than box ways and may be prone to deflection under heavy loads, potentially affecting accuracy and finish. They also offer less vibration damping.

- Shorter lifespan: While still durable, linear ways typically have a shorter lifespan than box ways and may require more frequent replacement.

- Higher cost: Linear ways are generally more expensive than box ways due to their design and materials.

Choosing the right option

Ultimately, the best choice between box ways and linear ways depends on your specific needs:

- For heavy-duty machining, hard materials, or applications requiring high accuracy and surface finish, box ways might be the better choice due to their rigidity and damping.

- For high-speed machining, applications requiring fast cycle times, or situations where space is limited, linear ways offer advantages in speed and precision.

- Consider your budget as well, as box ways are generally more affordable upfront.