Machine Tool Research, Inc Support

From a build, retrofit or the installation of a machine, machine alignment and further electrical or mechanical support, MTR is here for you every step of the way. MTR service technicians can be sent to your facility to repair or remove your machine or the machine components. We are capable of doing in-field corrections to reduce your machines’ down-time.

Shop Services

Electrical Shop Services

Assembly Shop Services

Faro Laser Tracker Service

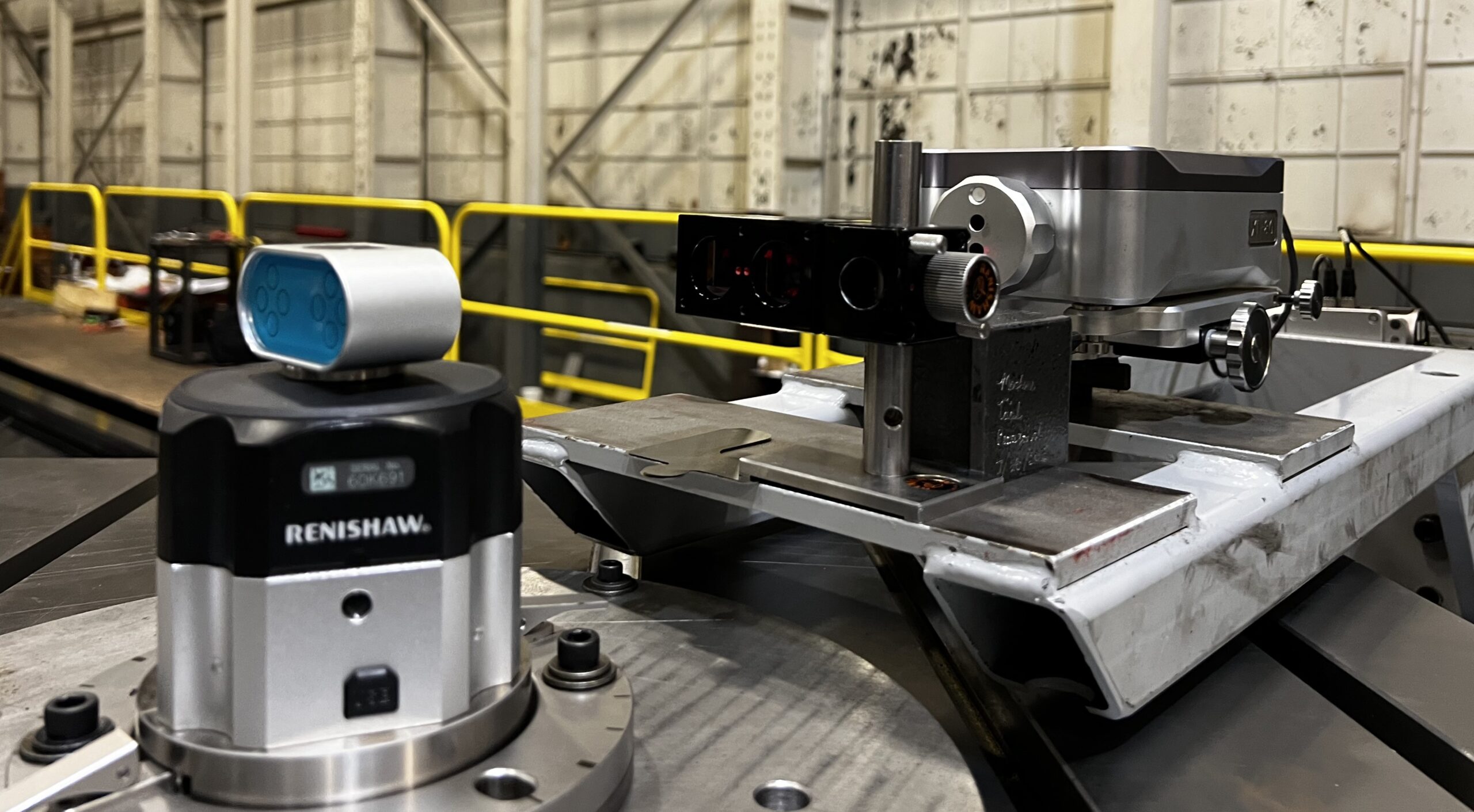

MTR uses its extensive knowledge of real-world measurement applications, to maximize the laser trackers ability to perform the following:

- Alignments that are accurate and less time-consuming than traditional methods

- Frequent measurements to show distortions in machine guideways

- Real-time measurements to confirm tolerances and validates alignments

- Lay-out and level machines

- MTR’s Laser Tracker service provides fast accurate surveys and enables us to capture a 3-D measurement quickly and easily, which allows us to see a much larger picture of how a machine really moves.

Renishaw Linear and Rotary Laser Services

Services Offered by MTR

When MTR began this business in 1982, we exclusively did service and repair work. Our customers were so pleased with our services that they began contracting with us to be their annual maintenance teams, shutdown crews, weekend repair crews, and more. Today we continue to support these efforts. We service almost every type of machine tool make and model. We specialize in larger machines and have the tooling and instrumentation to fix some of the world’s largest machine tools.

Analysis

Laser Calibration

Learn More About Our Services

Scraping

Emergency Repairs

Your new machinist just crashed your multi-million-dollar machine and you’ve got deadlines to meet. MTR, with its staff of trained technicians can be on site quickly, sometimes in a matter of hours. We, at MTR, have encountered numerous crashes and can resolve the crash without cutting corners to repair your machine. So, just because it looks bad doesn’t mean we can’t fix it.

For more information about our machine tool support services please contact us at 585-288-0320 today!

About

Machine Tool Research, Inc.

405 Blossom Road

Rochester, NY 14610

Contact Us

Phone: 585-288-0320

Fax: (585) 482-9078

Email: info@mtrnet.com

Hours

Monday – Friday

8:00 AM – 5:00 PM