Exceptional Machine Tools

Built in America by MTR

We Build Custom Machine Tools Suited for Your Industries Requirements

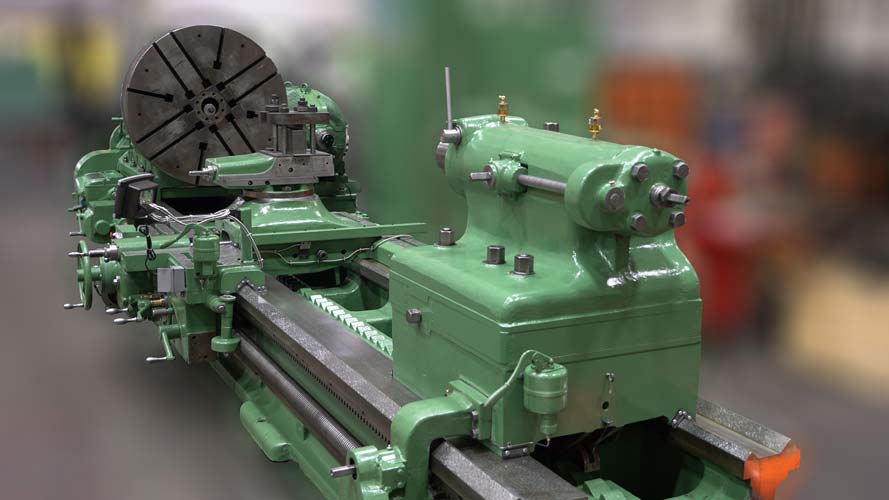

Lathe Features and Options

MTR has produced lathes with the following features and options for decades with great results for accuracy and machine rigidity:

Bed Sections

Two-Way Bed Sections

A cost-effective solution for a machine build but the carriage will not be capable of passing steady-rests or the tailstock.

Three-Way Bed Sections

Providing a larger machining envelope and more cost effective for larger scale machining. Again, the carriage will not be capable of passing the steady rests or tailstock unless the carriage, tailstock and steady-rests share a way surface.

Four-Way Bed Sections

Four-way beds allow the carriage to pass the steady-rests and tailstock to reduce machining time and setup time. Four-way beds also allow larger part diameters.

Carriage(s)

The carriage is wide and rigid to support the cross slide and tool slide(s). The carriage travels on the way guides on the bed with a positive guide way to provide precise, straight guiding. Carriage bearing surfaces may be hydrostatic, linear guide bearings, tychoway style bearings or low-friction bearing material such as bearing tape on aluminum or bronze with automatic lubrication systems. MTR can supply one or multiple carriages based on the requirements of the machine. If the machine has a two or three-way bed, multiple carriages may be beneficial to compensate for the fact you cannot move the carriage past a steadyrest.

Cross-Slide, Tool Supports

The cross-slide provides a means for the tool to move into or out of the part. This may contain a B-axis for milling and drilling on cylindrical parts. Like the carriage sliding ways, many options are also available for the cross-slide. We can fabricate and procure tooling fixtures requested by our customers to install in the tool support. MTR utilizes acme or ball screws for driving the cross-slide.

Carriage Drive

Platforms

Power Tracks

Steadyrests/ Workpiece Supports

Controls

MTR can outfit your VBM, VTL or Mill with the most current control systems available. We are Siemens Solution Partners and Fanuc Integrators. We also have a partnership with Heidenhain for integrating scales and encoders on your machine, they also provide controls if your shop is familiar with utilizing that system.

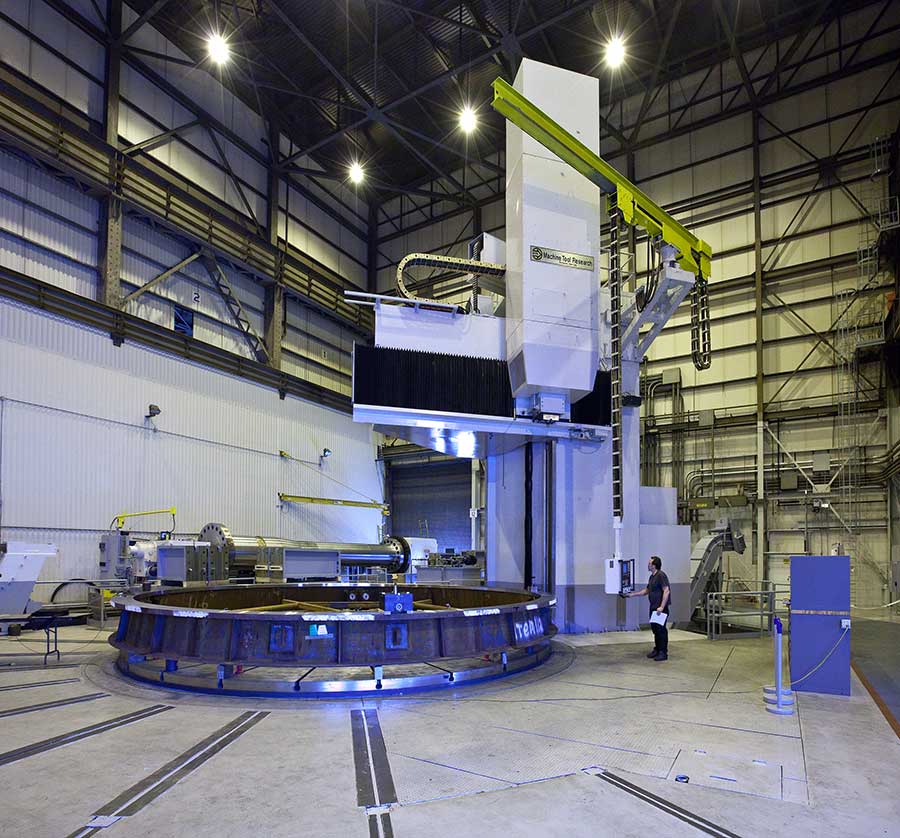

Vertical Boring Mill, Vertical Turning Lathe and Planer Mill Features and Options

MTR has produced Vertical Boring Mills and Opensides with the following features and options for decades with great results for accuracy and machine rigidity:

Table Bearing

Outdated table bearing systems in older VBMs can limit load and speed capacities. New hydrostatic or roller bearings will improve performance. Even plain bearing systems can be appreciably upgraded with modifications to bearing surfaces and lubrication systems.

Saddles(s)

The saddle on your VBM, openside or planer mill can be driven with a ground ball screw, or a twin-pinion anti-backlash system and can ride on plain bearings, linear rails or even hydrostatic bearings depending on your industries requirements. Your machine may require having multiple cutting heads and may benefit from having multiple saddles.

Ram(s)

The ram holds your tooling, whether that is a single point tool or a live spindle. If your parts require hard to reach machining, we have the capabilities to fabricate a head unit for the end of your ram with a live spindle. Depending on your application your ram may be round or square and have a plain bearing or hydrostatic bearing. The benefits to a hydrostatic bearing surface are improved stiffness and dampening characteristics of the tool support permitting deeper cuts and greater stock removal, while maintaining quality surface finishes.

Live Spindle(s)

Including a live spindle in your ram can provide milling and drilling options on your VTL, using the table as a positioning axis.

Cross-Rail

The cross-rail is the support to the saddle and ram. This requires a strongback to stiffen the cross-rail while the saddle travels. The cross rail may be a positioning axis or another machining axis, the difference will be demonstrated in the drive system and electronic feedback systems.

Central Lubrication Systems

New lubrication systems, in conjunction with the latest bearing materials and safety monitors, provide virtually failsafe lubrication throughout the machine.

Controls

MTR can outfit your lathe with the most current control systems available. We are Siemens Solution Partners and Fanuc Integrators. We also have a partnership with Heidenhain for integrating scales and encoders on your machine, they also provide controls if your shop is familiar with utilizing that system.

Controls

MTR can outfit your lathe with the most current control systems available. We are Siemens Solution Partners and Fanuc Integrators. We also have a partnership with Heidenhain for integrating scales and encoders on your machine, they also provide controls if your shop is familiar with utilizing that system.

About

Machine Tool Research, Inc.

405 Blossom Road

Rochester, NY 14610

Contact Us

Phone: 585-288-0320

Fax: (585) 482-9078

Email: info@mtrnet.com

Hours

Monday – Friday

8:00 AM – 5:00 PM