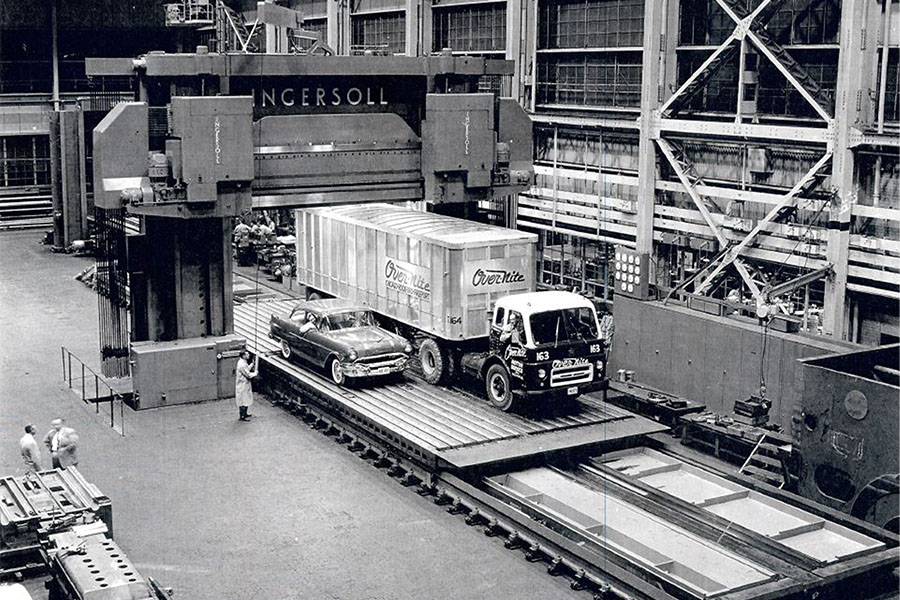

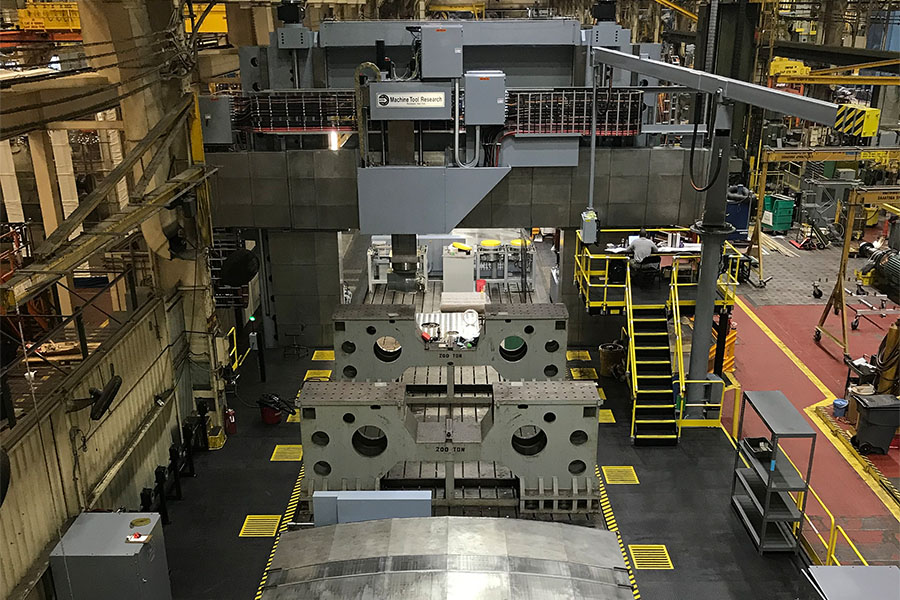

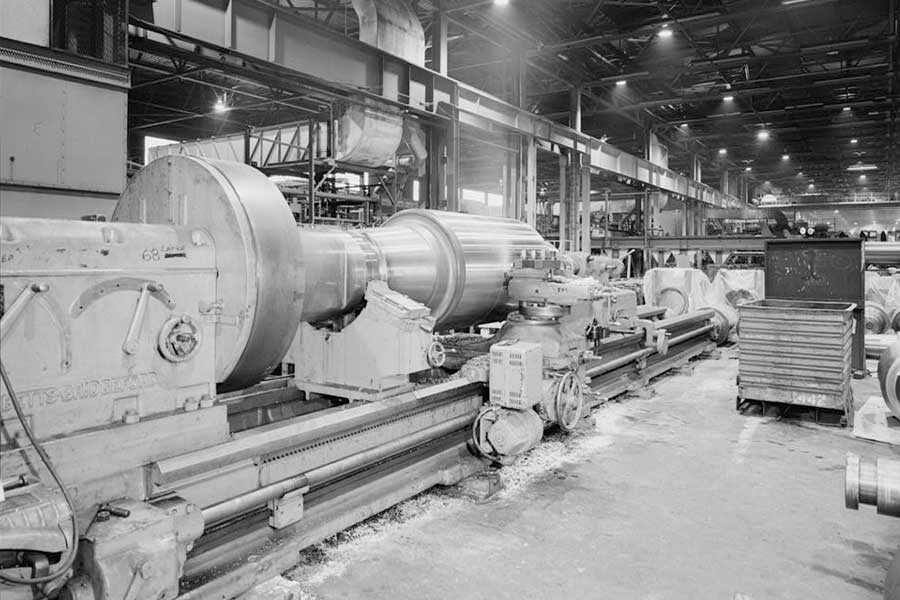

Machine Tool Research, Inc. has a long history of building and rebuilding machine tools. Replacement of your old, worn VBM, Lathe or other large machine tools, can be a huge capital investment. Fortunately, replacement may not be necessary to bring your machines’ controls, speeds, feeds and tolerances up to today’s standards. In most cases, MTR can rebuild or retrofit the majority of the machine tools out there to meet the specifications you require – for approximately two-thirds the cost of comparable new equipment.

MTR has partnerships with Fanuc, Seimens and Heidenhain, giving us the advantage of providing our customers with products, support and applications. We support PLC controls and other CNC control manufacturers to suit your shops requirements. Our controls engineers have the ability to design and implement a new control for your machine for your machine modernization. We have fabricated and installed updated CNC controls for decades.

Rebuilds

MTR has the capabilities of rebuilding your current machine to bring it back to OEM standards, replacing broken and correcting any worn items to keep your machine running like it once did and keep it running for years without complications. Rebuilding your machine may result in discovery of potential issues that may arise if the machine was run longer, resulting in a costly repair and machine down time. During our rebuild process we will completely disassemble and inspect all parts for rebuilding and replacement and make a report of all items found.

MTR has the following capabilities but is not limited to:

- Fabrication of weldments

- Hydraulic and hydrostatic upgrades and designs

- Grinding of centers

- Precision grinding spacers

- Tapered shoe repair and replacement

- Way and liner repair or replacement

- Scraping and inspecting contact and geometry of machine ways

- Screw alignments

- Bushing and bearing replacements

- Thread repair

- Joining machines together to add length or features

- DC to AC control conversions

- CNC upgrades

- Motor tuning

- Scale replacement and modernizations

- Setting gear contact and backlash

- Reverse engineering of outdated and no longer available parts

- Level and alignments

- Lubrication tuning and/ or replacement

- Bearing pre-loads

Retrofits

Does your shop have machines that are not frequently used because they are outdated, worn or incapable of performing enough work in your facility? MTR is here to offer solutions to make your shop more profitable, contact us today. Our application sales engineers can visit your facility and discuss options to modernize your current machines.

Types of Machine Tool Modernizations

Mechanical Builds, Rebuilds

and Retrofits

Manual to PLC or

Manual to CNC

CNC

Upgrades