Servicing America’s Largest

Machine Tools Since 1982

Machine Tool Research, Inc.

Servicing Large Machine Tools Nationwide

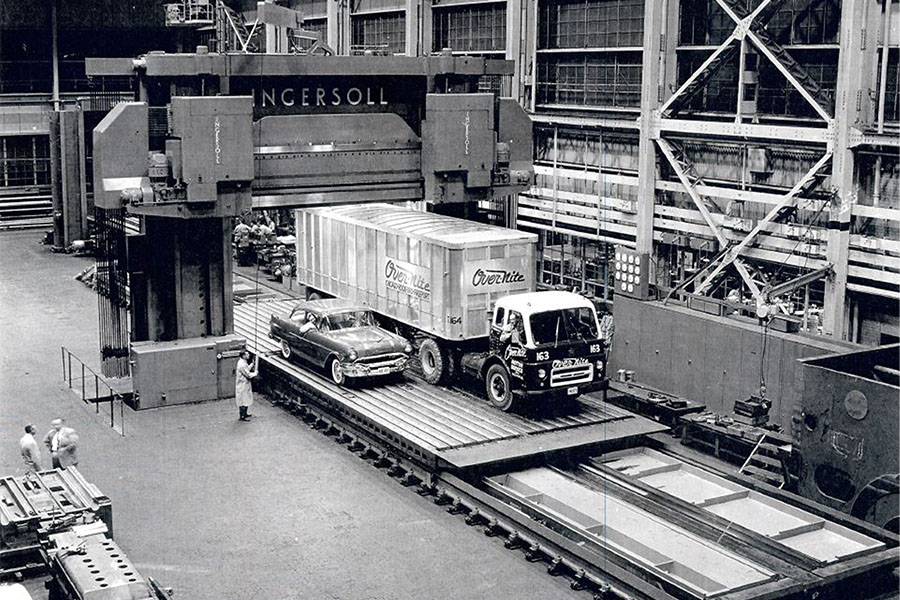

Machine Tool Research, Inc. (MTR) is the premier authority for machine tool knowledge in the US. MTR is a builder of new machines, as well as a rebuilder and retrofitter of vintage equipment. Using the most up to date CNC technology, MTR can bring your equipment into the modern age.

By employing a full staff of experienced mechanical and control engineers, no application is too complicated for MTR. MTR’s highly trained assembly and machine shop personnel bring your applications to reality.

Our customer support at MTR is most important, we will provide machine tool knowledge, quality assurance with professionalism

Our In-House Capabilities

Engineering

MTR employs a staff of professional mechanical and controls engineers that can handle the most complex machine tool applications and designs.

Manufacturing Capabilities

MTR has the following in-house capabilities:

- Milling

- Turning

- Surface Grinding

- Welding/ Fabricating

- Painting

- Assembly

Standards

Machine Build

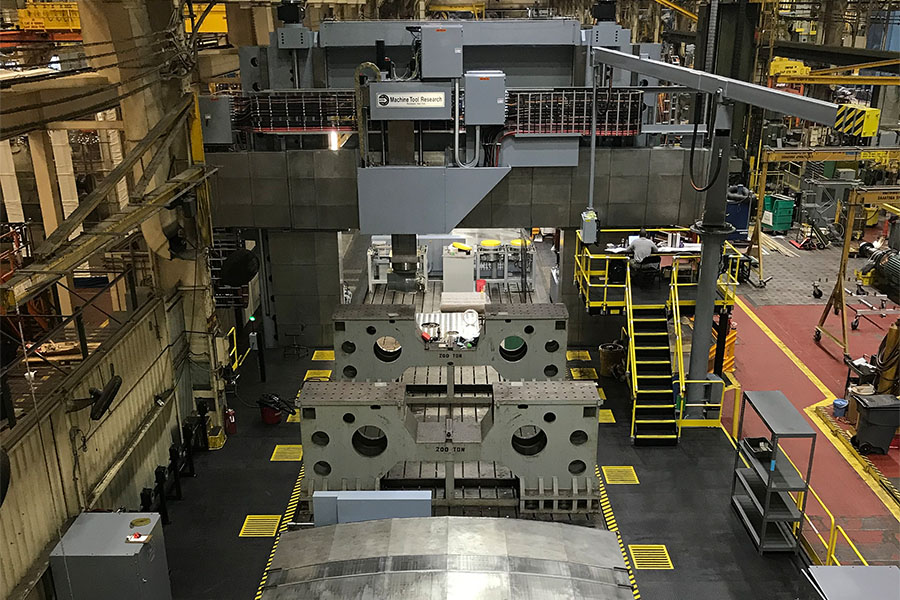

MTR occupies over 150,000 square feet of assembly space equipped with heavy lifting cranes in dual high bays with upgraded lighting and heating systems. Our experienced assembly technicians can work diligently and comfortably at MTR. With a large panel building shop between the assembly bays, MTR electrical technicians are able to build and test the most complex CNC systems.

See Our Results

How can MTR make your machines more productive and reliable?

About Us

Our History

Our Values

Our Lines and Services

FAQs

What machine tool services does Machine Tool Research, Inc. (MTR) offer?

Machine Tool Research, Inc. (MTR) specializes in building new machines as well as rebuilding and retrofitting vintage equipment. Utilizing the latest CNC technology, MTR modernizes equipment to enhance performance and extend lifespan.

How does MTR ensure quality in its machine tool rebuilds and retrofits?

MTR adheres to original equipment manufacturer (OEM) quality standards, ensuring that all rebuilds and retrofits meet industry-leading benchmarks. As the OEM for Farrel, Betts, and Sellers machines, MTR applies the same exacting standards to all serviced machines.

What industries does MTR serve with its machine tool solutions?

MTR serves a diverse range of industries by providing custom machine tool solutions tailored to specific requirements. Their decades of expertise in rebuilding and retrofitting large machine tools and having the drawings from Farrel and Betts powerhouse machinery caters to various sectors seeking enhanced manufacturing capabilities.

What in-house capabilities does MTR possess for machine tool services?

MTR boasts comprehensive in-house capabilities, including engineering, manufacturing, and assembly. Their machine shop capabilities range from milling, turning, surface grinding, welding/fabricating, and painting. The 150,000-square-foot assembly floor consists of a mechanical assembly and a panel building shop to construct some of the largest machine tools within our shop for runoff before installing in your facility. These services are supported by a team of experienced mechanical and control engineers, ensuring efficient and successful project executions.

How can I contact MTR for machine tool services or inquiries?

To learn more about MTR’s services or to request a quote, you can call them at 585-288-0320, or email them directly.

How can MTR support your machine shop?

Contact us or call us at 585-288-0320 today!

About

Machine Tool Research, Inc.

405 Blossom Road

Rochester, NY 14610

Contact Us

Phone: 585-288-0320

Fax: (585) 482-9078

Email: info@mtrnet.com

Hours

Monday – Friday

8:00 AM – 5:00 PM